Atrium Maintenance with ReechCraft’s Freestanding PowerMast

When you need to access difficult spaces that other equipment can’t reach, ReechCraft has the perfect solution! What began as a custom design for clients with unique access needs has now become one of our standard product offerings. Today, we want to share with you one of the first projects that used our PowerMast freestanding quad-mast system for atrium maintenance.

About Goodyear Tire & Rubber Company

Since their founding in 1898, Goodyear Tire & Rubber Company has been synonymous with high-quality, innovative tires for passenger vehicles, motorcycles, commercial trucks, and more. With their global headquarters in Akron, Ohio, and locations across 22 countries, Goodyear is one of the world’s largest tire companies, prioritizing innovation to drive them forward.

Navigating Maintenance Challenges

The Goodyear global headquarters in Akron has four large atriums that reach 80 feet in height. With glass curtain walls, internal and external windows, lighting, ground obstructions, raised and specialized flooring material, and bump outs limiting accessibility, these atriums were difficult to maintain. In addition, the only way to transport equipment into the space was to use elevators and stairs. This presented numerous issues for typical access equipment. Although scaffolding could reach the needed heights, it was time-consuming and took days to set up, move, and tear down.

Providing Modular Access

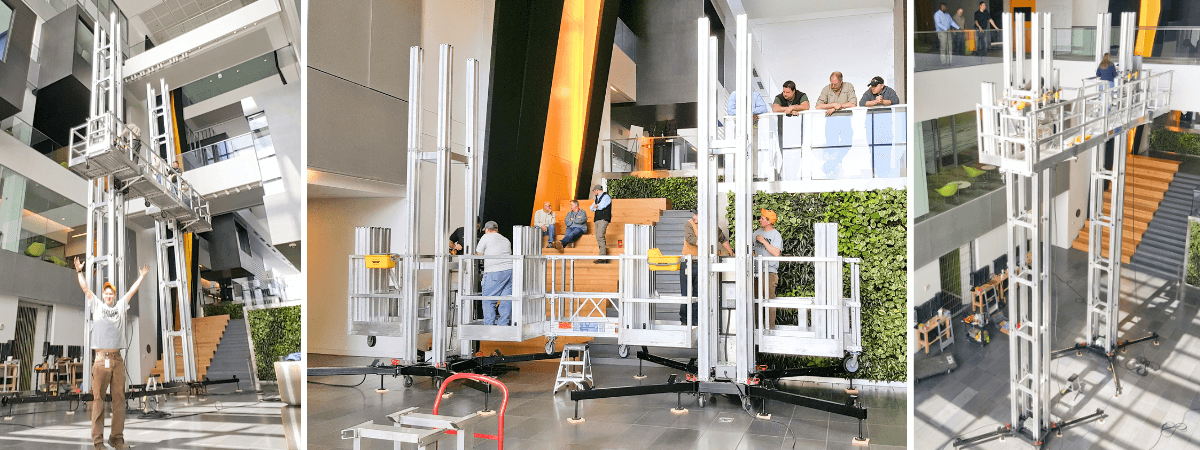

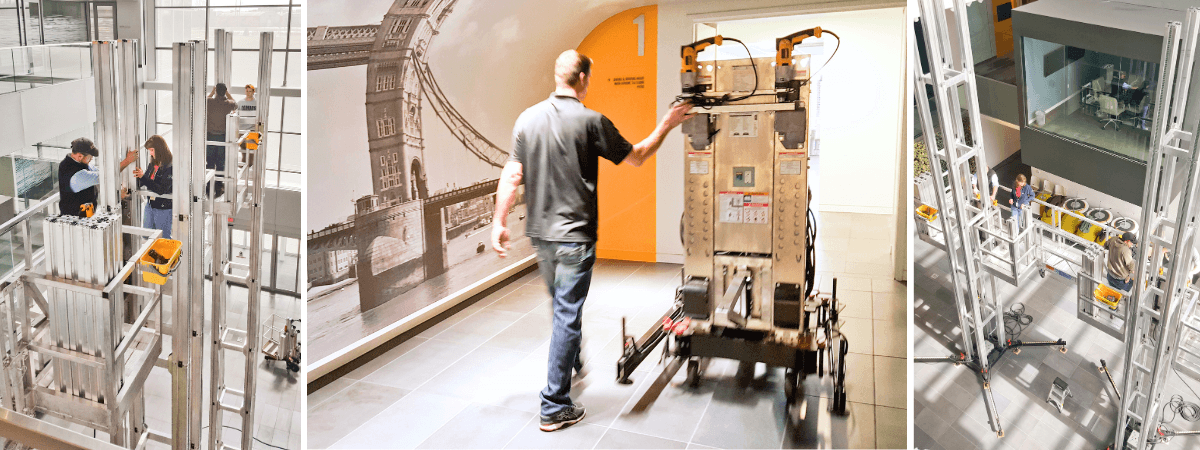

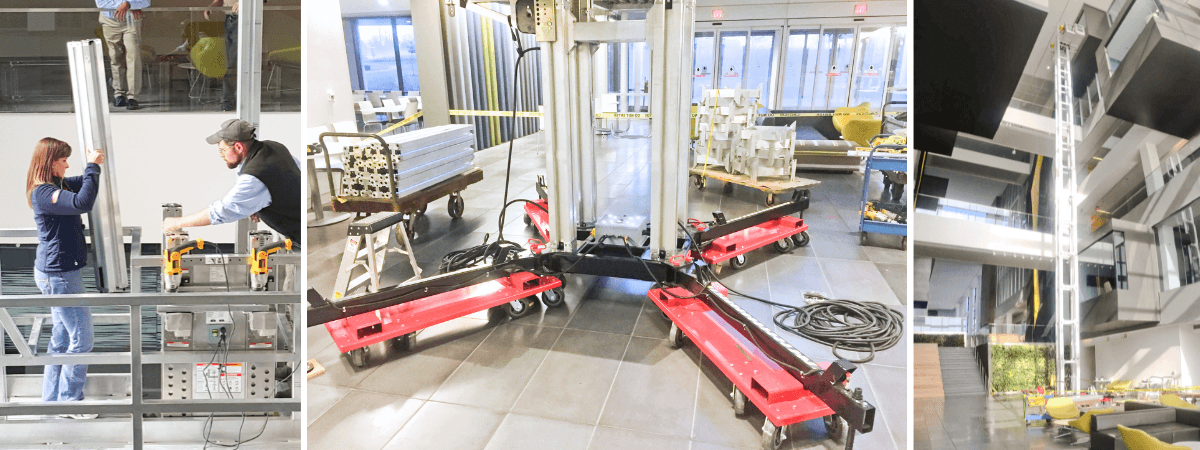

To solve Goodyear’s access problems, ReechCraft developed a custom PowerMast freestanding quad-mast system. Using standard components from our PowerMast wall-tied system and adding some custom assemblies, we created a modular solution that could be used in a single or twin configuration.

For this system, we combined four masts with a custom tie bracket to form one rigid, freestanding tower. We built platforms for both the single and twin configurations and developed an outrigger base that disperses the weight of the system for minimal PSI on the floor. The base also allowed the system to be operated safely and solidly at the required 80-foot working height.

ReechCraft’s PowerMast freestanding quad-mast system can be set up in under two hours and can be moved to different areas while assembled. Other access methods had to be left in one place or completely disassembled and set up again to move. None of the alternatives met the time or height requirements needed to access the atriums. Finally, PowerMast components are extremely portable, so workers were able to transport the system with ease using elevators and stairs.

An Economical Solution

“This is the first time since this building was constructed that we’ve been able to access the top of the atrium to change lights and clean the windows. This custom setup offered an economical and logistically-friendly option for reaching the atrium space while addressing concerns and issues presented by alternative access methods,” said Valerie Bigler, Senior Facility Manager with IRG Realty Advisors, who maintains the building.

With this cost-effective solution, the facilities maintenance personnel can now reach the needed heights in the atrium without costly rentals or extensive scheduling delays. Even fully assembled, the PowerMast freestanding quad-mast system takes only two people to move, helping to complete jobs faster and bring costs down.

About ReechCraft

Since our founding in 1993, ReechCraft has set itself apart with innovative products and first-rate services. We strive to find new access solutions to meet the needs of every craftsman. If you have questions about any of our American-made products, have a custom application, want to place an order or would like additional information about our dealer program, give us a call at (888) 600-6160 or fill out our online contact form.