Tackling Church Facility Maintenance With PowerLift

Church facility maintenance can often feel like an overwhelming challenge. The endless tasks of servicing audio/visual equipment, regularly changing lightbulbs, repairing delicate historical features like stained-glass windows, and, of course, the annual Christmas decorating, usually fall on the shoulders of volunteers.

With most volunteers having only a few hours after Sunday service to help, it’s crucial to have an efficient way to tackle all these tasks. Without it, you might end up hiring external contractors for those hard-to-reach jobs or even attempting them yourself.

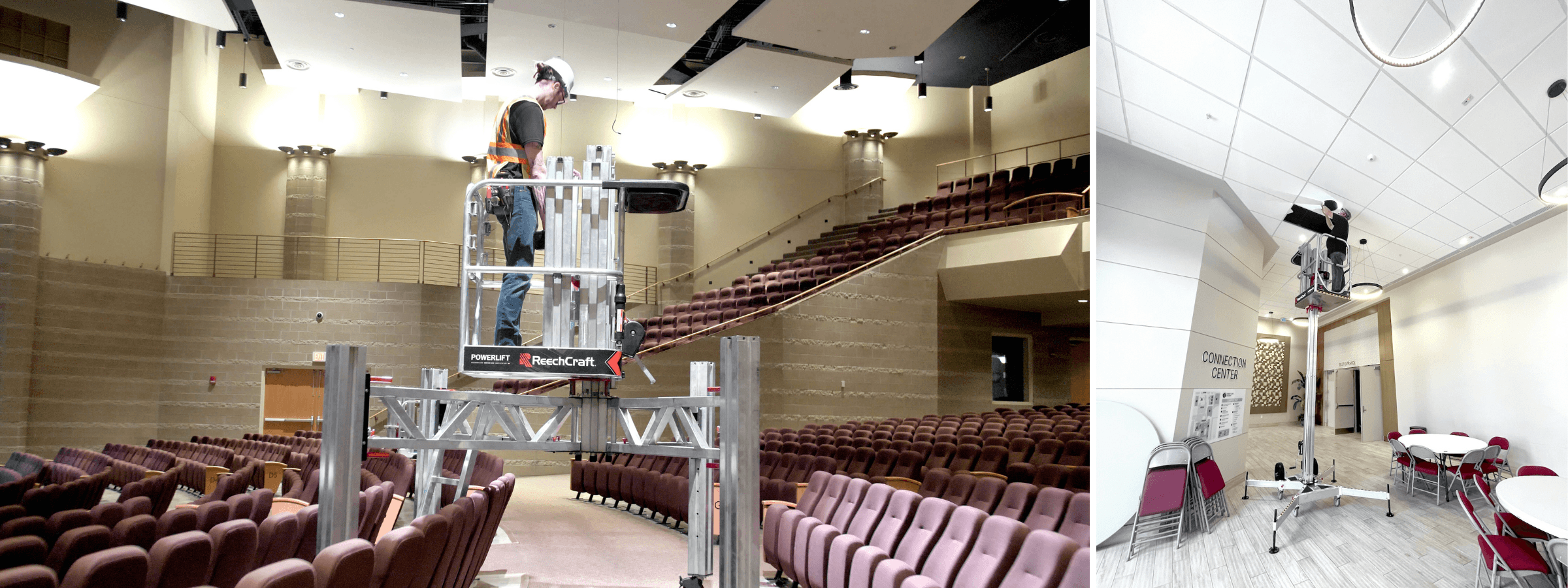

We are thrilled to share how our PowerLift transforms maintenance for churches across the country, cutting their maintenance time in half, enhancing the safety of church volunteers, and significantly reducing external hiring costs.

Church Maintenance Headaches

Lacking a portable, stable access option like PowerLift, many churches face numerous challenges with maintenance tasks. They rely on scaffolding for changing ceiling lights, ladders for hanging decorations or fixing speakers, and sometimes hired external maintenance for hard-to-reach last-minute repairs. Their frustrations are clear.

Time-Consuming

Setting up and tearing down scaffolding is a labor-intensive process, often taking up to three days and requiring several volunteers. Bulky scaffolding is difficult to maneuver around pews, stairs, and podiums, making maintenance in high places a logistical nightmare. Emergency repairs can be nearly impossible to handle in-house.

Expensive

Due to the time-consuming nature of their equipment, churches often have to hire external help for last-minute repairs, which quickly becomes costly. If a ceiling light burned out on Saturday, there wouldn’t be enough time to set up and take down scaffolding before Sunday service, leading to expensive external hires.

Unsafe

Improperly assembled scaffolding poses significant safety risks, and volunteers, not professionally trained, put themselves at risk of falling. Utility ladders, while simpler, require volunteers to balance precariously while reaching above their heads, increasing the risk of accidents. High ceilings are unattainable when using ladders.

Damaging Church Historical Features

The beautiful, historic features in many churches, such as hardwood floors, wall art, and stained-glass windows, risk being damaged by scaffolding and ladders; this equipment can damage both floors and walls—particularly if the walls are older and not designed to bear such weight. These historical features are integral to the church’s community and worship experience, making their preservation crucial.

PowerLift completely changes a church’s approach to maintenance, decoration, and building repairs.

Church Maintenance with PowerLift

ReechCraft understands the frustrations that come with maintaining church facilities, and that’s why we have a solution for access problems like these. Our modular PowerLift is a game changer for church maintenance.

Efficient

PowerLift significantly reduces the time required for setup and teardown. Unlike scaffolding, which can take days to assemble and disassemble, PowerLift can be set up quickly by a single person. This efficiency allows volunteers to complete tasks in a fraction of the time, reducing the need for extensive preplanning.

Enhanced Safety

Safety is a top priority, and PowerLift excels in this area. It provides a stable and secure platform for volunteers to work from, reducing the risk of falls and injuries associated with ladders and scaffolding. The system complies with ANSI and OSHA safety standards, ensuring that volunteers can perform their tasks safely.

Protecting Historical Features

The compact and maneuverable design of the PowerLift minimizes the risk of damage to delicate and historical church features. Its small footprint allows it to navigate tight spaces without causing harm to floors, walls, or other valuable features of the church. This is particularly important for preserving the aesthetic and historical integrity of the church.

Cost-Effective

By eliminating the need for scaffolding and reducing the reliance on external contractors, PowerLift helps churches save money. The ability to quickly address maintenance issues in-house means fewer emergency calls to costly repair professionals. This system allows churches to allocate their budget to other important areas.

Versatility and Accessibility

PowerLift is designed to handle a variety of maintenance tasks. With multiple standard, pre-built models such as the compact and outrigger units, as well as a completely modular system with four base options, it can be configured to suit different needs and environments. Maneuvering around pews, podiums, staircases, and other obstacles is simple with PowerLift. Whether it’s changing lightbulbs, repairing audio/visual equipment, or decorating for special events, PowerLift provides easy access to every hard-to-reach area.

PowerLift has revolutionized the way churches approach maintenance. By addressing the challenges of time, cost, safety, and preservation, it has become an invaluable tool for ensuring the smooth operation and upkeep of their facilites. With PowerLift, volunteers can focus on their service without the added stress of cumbersome and risky maintenance tasks. PowerLift truly makes church maintenance simple, efficient, and safe.

Interested in learning more about how PowerLift can revolutionize the way you tackle church facility maintenance? Follow the link below to browse PowerLift options, see pricing, or reach out to our team.

About ReechCraft

Since our founding in 1993, ReechCraft has set itself apart with innovative products and first-rate services. We strive to find new access solutions to meet the needs of every craftsman. If you have questions about any of our American-made products, have a custom application, want to place an order or would like additional information about our dealer program, give us a call at (888) 600-6160 or fill out our online contact form.