From all of us at ReechCraft, we wish you and yours the best this Holiday season!

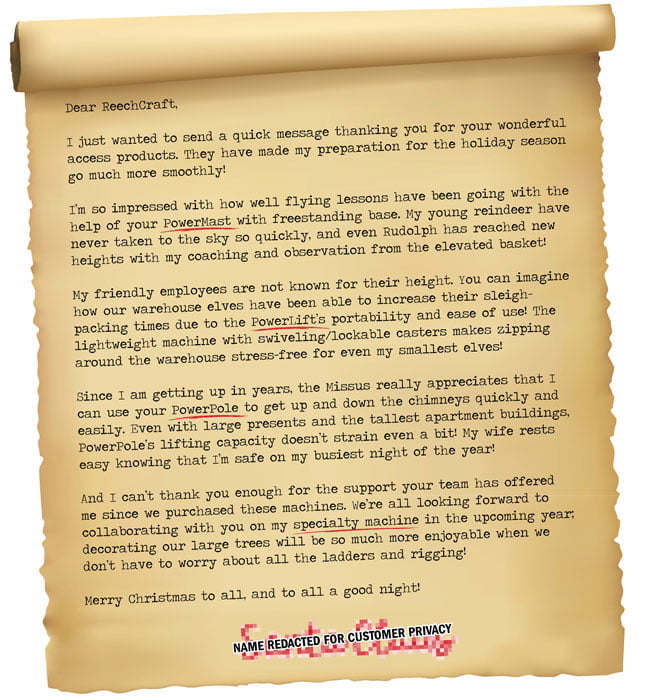

From time to time, we like to highlight how our customers are utilizing their ReechCraft equipment. This week, we received an especially thoughtful letter that we would like to pass along to you!

About ReechCraft

Since our founding in 1993, ReechCraft has set itself apart with innovative products and first-rate services. We strive to find new access solutions to meet the needs of every craftsman. If you have questions about any of our American-made products, have a custom application, want to place an order or would like additional information about our dealer program, give us a call at (888) 600-6160 or fill out our online contact form.

Connect With Us Online!